Shuttle Robot: Revolutionizing Warehouse Operations in Kazakhstan

In recent years, the logistics industry in Kazakhstan has witnessed a significant transformation with the introduction of advanced technologies. One such innovation is the shuttle robot developed by HWArobotics, which has revolutionized warehouse operations across the country.

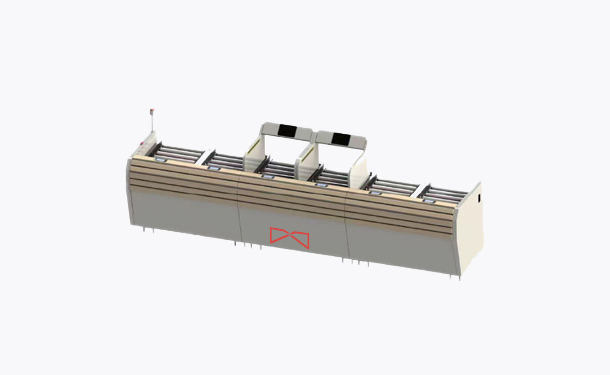

The SLS500: Enhancing Short-Term Storage and Sorting Efficiency

The SLS500 is a state-of-the-art shuttle system designed for short-term storage and sorting large numbers of goods. This cutting-edge technology utilizes flow racking to support warehouses with high throughput, multiple aisles, and large storage depths.

With its first-in-first-out mechanism, the SLS500 enables fast automatic replenishment and ensures high storage and retrieval efficiencies. Its effective hybrid storage location design allows for a high storage density, maximizing space utilization within warehouses.

Moreover, this innovative system features multiple runners and deep locations that can buffer a substantial quantity of goods. By effectively managing peak and off-peak replenishments, it optimizes operational efficiency while maintaining an organized inventory management process.

The Shuttle Robot: Streamlining Warehouse Processes

A key component of the SLS500 system is the shuttle robot itself. These autonomous robots work seamlessly alongside human operators to streamline various warehouse processes.

Equipped with advanced navigation systems and sensors, these robots efficiently transport goods between different locations within the warehouse. They are capable of handling diverse sizes of inbound items, ensuring compatibility with most products stored in warehouses.

This integration of shuttle robots into warehouse operations significantly reduces manual labor requirements while improving overall productivity levels. It also minimizes errors associated with traditional manual picking methods by providing accurate item tracking throughout each stage of order fulfillment.

Promising Future Prospects

The implementation of shuttle robots in Kazakhstan’s warehouses has already showcased remarkable results. The enhanced efficiency and accuracy achieved through this advanced technology have led to significant cost savings for businesses.

As the logistics industry continues to evolve, it is expected that shuttle robots will play an increasingly vital role in optimizing warehouse operations. With their ability to handle large volumes of goods, ensure quick replenishment, and maximize storage space utilization, these robots are poised to revolutionize the way goods are stored and sorted in Kazakhstan.

In conclusion

<img “=”” height=”119″ https:=”” products=”” src=”https://www.<a href=” tote-shuttle-robot-system=”” www.hwarobotics.com=””/>hwarobotics.com/wp-content/themes/default/images/download.jpg” width=”400″/>

The introduction of shuttle robots by HWArobotics has brought about a paradigm shift in warehouse operations across Kazakhstan. By combining cutting-edge technology with efficient design principles, these systems have proven instrumental in enhancing short-term storage and sorting efficiency while streamlining various processes within warehouses. As the country embraces further advancements in logistics technologies, shuttle robots are set to become an indispensable asset for businesses seeking improved productivity and cost-effectiveness.